While any car carrying the Ferrari badge is inspirational to enthusiasts, there are certain models that seem even more infused with the magic that has made this the most desirable sports car brand on the planet.

These particular models achieve instant cult status through a combination of looks, performance and rarity, and if they are genuinely exceptional cars, their provenance will only be reinforced as time goes by. However, just the fact that a particular Ferrari model is the most expensive or limited in production numbers does not always guarantee it a place at the top table.

While the F40 was king of the hill in the early ‘90s, and to this day is the stuff of legends, the F50 that succeeded it received a relatively lukewarm reception and has never been seen in the same light. Conversely, the Enzo was the Ferrari of the moment from day one and is still considered one of the seminal supercars of all time.

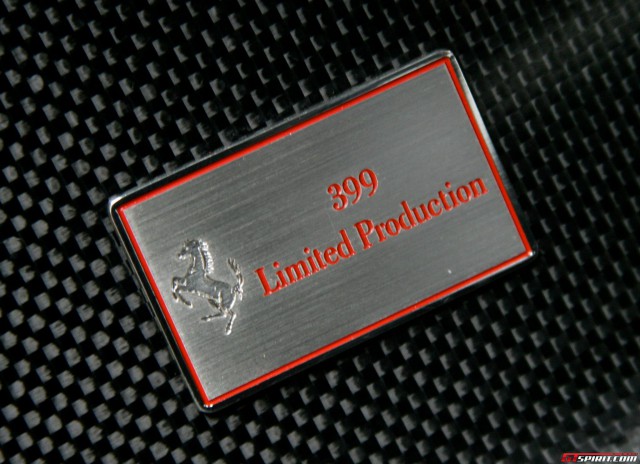

Officially, Ferrari built 399 Enzos, a tribute to the F399 Formula One racer that swept the board in 1999, winning the Constructors title for Ferrari.

A 400th car was built as a gift to the late Pope John Paul II, and subsequently auctioned by Sotheby’s on behalf of his successor, Pope Benedict XVI. The proceeds of US$1.1 million were donated to the victims of the Tsunami that year.

Unlike the mighty F40, whose values took a tumble in the early part of the 21st Century, before recovering on the back of Ferrari’s relentless F1 winning streak, the value of the Enzo has been consistently creeping upwards, and any perfect example is now a million dollar car.

However, it is a fact of life that very powerful supercars often fall into the hands of clientele whose driving skills fall short of the cars abilities, and sadly around 15 Enzos have been crashed. Of course the cynical will say that this has increased the value of the survivors!

Many Enzos are in private collections and are hardly, if ever driven. Thankfully, not all wealthy collectors see cars as objects ‘d art to be salted away, and some owners actually take their four-wheeled treasures out for an airing, so that both they and onlookers can enjoy them.

Some supercars promise more than they deliver, but the Enzo, designed by Ken Okuyama under the aegis of Pininfarina, drives exactly as it looks, and absolutely as you would expect it to.

If you have driven an F430, its older, bigger brother is not that much different in the way things work. That said, the functions of the later F430’s steering wheel mounted ‘manettino’ switch that allow you to select Road, ASR off and Race, are looked after by three separate buttons on the wheel of the Enzo.

The paddle shifters and the separate Start button are similar, except that the Enzo’s big red button is on the centre console rather than the steering wheel. The one feature that the Enzo has over the F430 is height adjustable front suspension for clearing steep ramps.

Strapped in, seat and mirrors adjusted, you turn the key in the ignition. A pull on both paddles ensures we are in Neutral, and then you push the red button. The 5,998cc litre DOHC V12 bursts into life with a bark from its exhaust that could probably be heard a mile away on a still night out in open country.

The electronic management ensures that the motor settles down immediately, but even this significantly subdued mechanical concerto echoes down the street, its sound components at fast idle not far off what you would hear in the pits at a race meeting. Stealth is not part of the Enzo’s repertoire at any speed!

Pull the right paddle towards me to select first gear, drop the fly-off handbrake to the left of the seat and apply gentle pressure to the throttle. The Enzo moves off smoothly, the immense torque of its V12 just off idle easily neutralising its mass.

Rated at 651bhp at a screaming 7,800rpm, 400rpm short of its cut-out, the race inspired motor has a mighty 657Nm of torque at 5,500rpm. With just 1,365kg to haul, this mega-motor will catapult the Enzo to 100km/h in 3.14sec, to 160km/h in 6.6 sec and on to around 350km/h.

As the oil and water need to warm through, you make an upshift at 3,500rpm, taking the time to feel how the car moves down the road. The paddle shift arrangement suits the driver fine and is a far cry from the recalcitrant dogleg manual gearbox in my Daytona, which effectively denies you selection of second gear when cold.

Even limbering up, the Enzo more than hints at what is to come. Its power-assisted steering is light to medium weight, but so full of feedback that you could imagine grading the size of the stones on the road blindfolded. Despite its obvious physical width, the carbon-fibre construction and resultant modest kerb weight means that the Enzo feels light and responsive even at town speeds.

This relatively low mass, coupled to the big, torquey, normally-aspirated motor is a recipe for hair-trigger acceleration, and once things are warmed up, the experience is both mind blowing and addictive.

Press the throttle progressively, and the Enzo surges forward with an instant and incredibly rabid urgency. Even with the electronics in Road mode, upshifts are fast, and the acceleration relentless.

Lifting the throttle slightly to anticipate the next ratio, is a good technique to use in all cars with clutchless manual gearboxes, allows fairly seamless upshifts. In Race mode though, the upshift speed makes smoothness hard to achieve, and when you are blatting round racetrack, is of less consequence anyway. On downshifts, the electronics blip the throttle for you, making you sound like a hero to bystanders.

The complex soundtrack from behind your head is simply amazing, a rhapsody of intake, exhaust and sheer mechanical activity that changes pitch and intensity with engine speed. But when you are concentrating hard on an unfamiliar road, the flurry of other inputs can overwhelm your senses to the point where even this heroic soundtrack recedes into the background.

With any powerful rear-drive car, warming the tyres properly before applying a lot of throttle is a given. The massive torque and quick throttle response of cars like the Enzo and Carrera GT make it very easy to unhinge the rear on cold tyres.

From experience, you should expect this, and a quick flick of the wrist as the wide, red tail moves out of line halfway through a spirited application of power in second gear instantly stops the slide. But it would be all too easy for someone caught unawares to lose the car, even at modest speeds. The handful of Enzos crashed, even at not too far above legal urban speeds is a testament to this.

Once the rubber is properly warmed, mechanical grip is impressive, but you really do have to be aware of the road surface and not over-drive the car into bends. The rear-biased weight distribution means that big understeer is waiting to catch out anyone who enters a tight turn carrying too much speed.

Power oversteer is there for the asking on the way out, but while this is huge fun on a race track, it is not advisable on public roads. Apart from anything else, the Enzo is very wide, and touching a kerb or any other solid object would be disastrous.

It may look brutal, but the Enzo is far from a blunt instrument. A sensitive and communicative partner that you need to feel your way with, it responds best to gentle inputs and clearly dislikes being prodded. This is a car that talks to you all the time, but when it begins to raise its voice, you need to listen.

Drive smoothly and progressively and it will tell you through its steering and the seat of your pants when you are approaching the limit, and therefore how much power the available grip can cope with. Get that bit clear and the rewards are both immense and on several levels. But you need to take your time to learn it.

The good thing is that instant gratification is there at all speeds, and as you get to know the car better, you will uncover more layers of its personality. There is little chance of anyone getting bored with Enzo ownership, even over time.

The last Enzo left the factory in Modena in 2004, but the adulation has not stopped. If anything, it has risen to deafening levels. I am happy to add my own voice to the chorus.